In modern industrial production lines, conveyor belts are an indispensable and important tool. They undertake the important task of material transportation and ensure the efficiency and stability of the production process. However, with the continuous expansion of industrial application fields, the demand for conveyor belts has become increasingly diverse. Today, we will discuss in depth the differences between patterned conveyor belts and oil-resistant conveyor belts to help you better understand the characteristics and application scenarios of these two conveyor belts.

1. Pattern conveyor belt: leader in anti-skid and heavy-duty

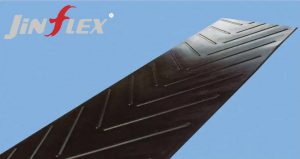

Pattern conveyor belt, as the name suggests, has a specific pattern design on its surface. This design not only enhances the anti-skid performance of the conveyor belt, but also makes it perform well in heavy-duty material transportation. Patterned conveyor belts are usually used in mining, metallurgy, construction and other industries, especially where heavy materials such as ore, coal, sand and gravel need to be transported.

The advantages of patterned conveyor belts are their strong load-bearing capacity and excellent anti-skid properties. The pattern design can increase the friction between the conveyor belt and the material, effectively preventing the material from slipping and accumulating during transportation. At the same time, the patterned conveyor belt is made of high-strength materials and can withstand greater pressure and impact, ensuring the safety and stability of material transportation.

2. Oil-resistant conveyor belt: a powerful assistant in the chemical industry

Oil-resistant conveyor belts are conveyor belt products designed for specific industrial environments. It is mainly used to transport materials containing chemical substances such as grease and solvents. In the petroleum, chemical, food and other industries, oil-resistant conveyor belts play a vital role.

Oil-resistant conveyor belts are characterized by their excellent oil resistance. It is manufactured using special materials and processes to maintain stable performance despite prolonged exposure to chemicals such as grease and solvents. In addition, oil-resistant conveyor belts also have good wear resistance and stretch resistance, ensuring efficient and stable material transportation in harsh industrial environments.

3. The difference between pattern conveyor belt and oil-resistant conveyor belt

1. Application scenarios: Patterned conveyor belts are mainly used for transporting heavy-duty materials, while oil-resistant conveyor belts are more suitable for transporting materials containing chemical substances such as grease and solvents.

2. Performance characteristics: Pattern conveyor belts focus on load-bearing capacity and anti-skid performance, while oil-resistant conveyor belts emphasize oil resistance and stability.

3. Material selection: Pattern conveyor belts are usually made of high-strength materials, while oil-resistant conveyor belts are made of special materials and processes to ensure their oil resistance.

4. Price difference: Due to differences in materials, processes and performance, the price of oil-resistant conveyor belts is usually slightly higher than that of pattern conveyor belts.

To sum up, there are significant differences between patterned conveyor belts and oil-resistant conveyor belts in terms of application scenarios, performance characteristics, material selection and price. When selecting conveyor belts, reasonable selection should be made based on the specific industrial environment and material characteristics to ensure the efficiency and stability of the production process.

+ There are no comments

Add yours