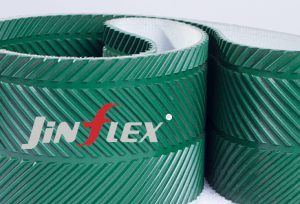

On the stage of material transportation, pattern conveyor belts and large-angle corrugated edge conveyor belts each have their own merits. The unique pattern design on the surface of the pattern conveyor belt increases the friction with the material, thereby effectively preventing the material from sliding and ensuring smooth transportation. This feature makes it popular in industries with extremely high hygiene and safety requirements, such as food and medicine.

In contrast, high-angle corrugated edge conveyor belts stand out for their unique high-angle conveying capabilities. Its corrugated rib design allows materials to be conveyed along larger inclination angles, which not only improves efficiency but also reduces floor space. This advantage makes it the first choice in industries such as mining and construction that require efficient, large-angle conveying.

In site applications, both conveyor belts have their own emphasis. Patterned conveyor belts are more suitable for occasions that require smoothness and anti-slip, such as food, medicine and other industries; while large-angle corrugated edge conveyor belts are better at handling large-angle, high-efficiency transportation needs, such as mining, construction and other industries.

However, this does not mean that the two cannot be substituted for each other. In some special scenarios, based on actual needs, the two conveyor belts can complement each other to achieve the best conveying effect.

In short, pattern conveyor belts and large-angle corrugated edge conveyor belts have their own characteristics in site applications. Understanding their characteristics and advantages will help us choose the appropriate conveyor belt according to actual needs and improve the efficiency and safety of material transportation.

+ There are no comments

Add yours